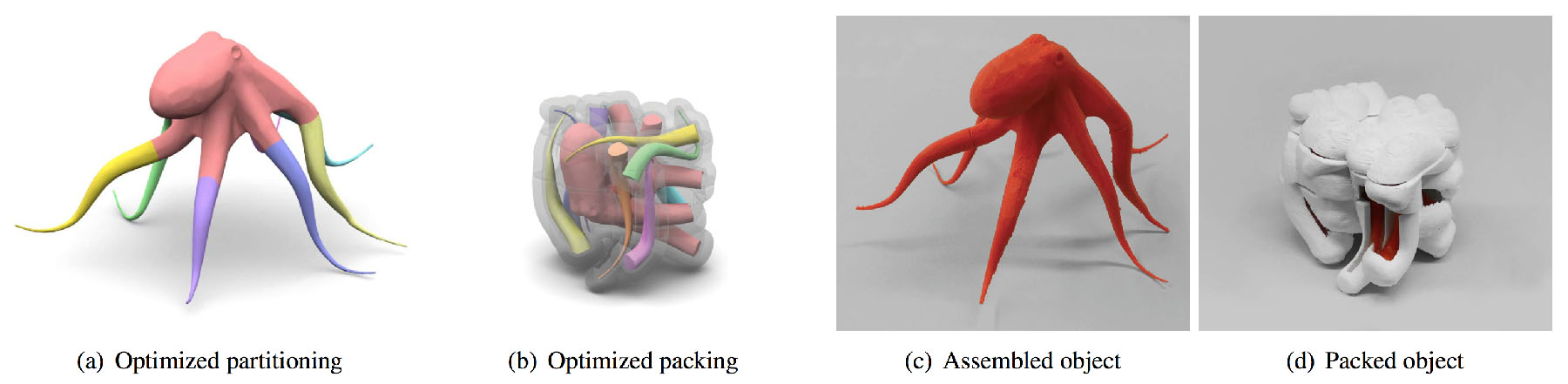

The octopus example. Our constrained partitioning optimization system automatically generates the partitioning of this octopus model, which contains nine pieces as shown in (a) and (c). These nine pieces can be packed into a box container as shown in (b) and (d), which occupies only 10.4 percent of its original container volume.

As the 3D printing technology starts to revolutionize our daily life and the manufacturing industries, a critical problem is about to emerge: how can we find an automatic way to divide a 3D model into multiple printable pieces, so as to save the space, to reduce the printing time, or to make a large model printable by small printers. In this paper, we present a systematic study on the partitioning and packing of 3D models under the multi-phase level set framework. We first construct analysis tools to evaluate the qualities of a partitioning using six metrics: stress load, surface details, interface area, packed size, printability, and assembling. Based on this analysis, we then formulate level set methods to improve the qualities of the partitioning according to the metrics. These methods are integrated into an automatic system, which repetitively and locally optimizes the partitioning. Given the optimized partitioning result, we further provide a container structure modeling algorithm to facilitate the packing process of the printed pieces. Our experiment shows that the system can generate quality partitioning of various 3D models for space saving and fast production purposes.